News

Contact us

- Address:

N.O. 53 Nanhuan Road, GongMing, Shenzhen, GuangDong Province, China (Post code 518107). - Zipcode:518109

- Email:info@ariseled.com

- Tel:+86-(0)755-6680-1409

- Mobile:+86 136 2020 9526

- Web:http://www.ariseled.com

Difference between three LED display light sources

As we know, the light source is very important materials for LED display performance and stability, because light source determines LED display consistency, viewing angle, brightness, and also the production cost. Now we will introduce the differences between dot matrix, DIP and SMD LED.

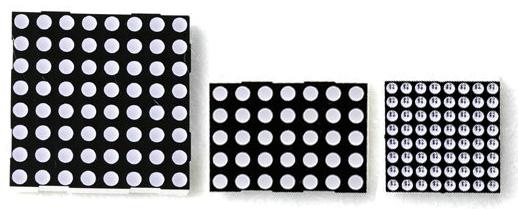

1. Dot matrix is a old design, and it was evolved from the interior pseudo-color dot matrix screen. It is of low cost of raw materials, simple production process, also stable quality. But recent years, seldom factory produce do matrix LED display any more, because it is has the disadvantages of poor color consistency,poor color reproduction, and mosaic phenomenon.

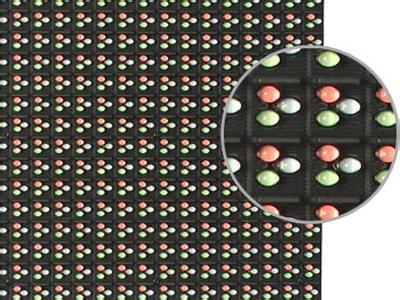

2. DIP LED: In order to solve the color problem of dot matrix screen, and supply outdoor display solution, manufacturers adopt DIP LED for light source.

In order to remedy the disadvantages of the color problem of dot matrix, and also for higher outdoor resolution, manufacturers choose to adopt DIP LED as light sources. DIP LED is of better color consistency than dot matrix module, and is waterproof for outdoor application, can work with pixel sharing technology, which is also named virtual pixel technology. Anyway, the DIP LED demands higher anti-static level, and the process of DIP is more complicated than matrix, so it is difficult to be applied to LED display whose resolution is above 10,000 pixels per square meter.

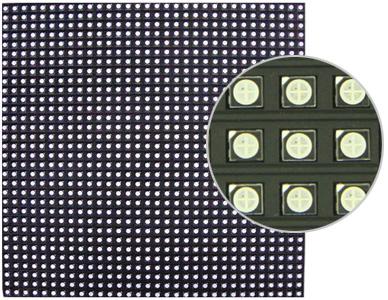

3. Then there is SMD LED, which is usually applied to pixel pith LED display screens. SMD LED is of very good color consistency, and it is viewing angle is better than DIP. Also it is with very good mixing color, can be for high resolution. It can be applied to indoor LED display,and also outdoor LED display(such as P6mm and P8mm outdoor LED display). The only thing is that the production process is very strict, and the cost is accordingly higher than matrix and DIP LED.