News

Contact us

- Address:

N.O. 53 Nanhuan Road, GongMing, Shenzhen, GuangDong Province, China (Post code 518107). - Zipcode:518109

- Email:info@ariseled.com

- Tel:+86-(0)755-6680-1409

- Mobile:+86 136 2020 9526

- Web:http://www.ariseled.com

Guideline for SMD LED soldering

POSTED ON SEPTEMBER 4, 2013 BY ADMIN IN LED COMPONENT, LED KNOWLEDGE WITH THERE ARE NO COMMENTS

1. Hand soldering:

a) A soldering iron of less than 20W is recommended to be used in handing soldering. b) Please keep the temperature of the soldering iron under 360 degree while soldering. c) Each terminal of the LED is to go for less than 3 second and for on time only.

d) Be careful, because the damage of the product is often stared at the time of the hand soldering.

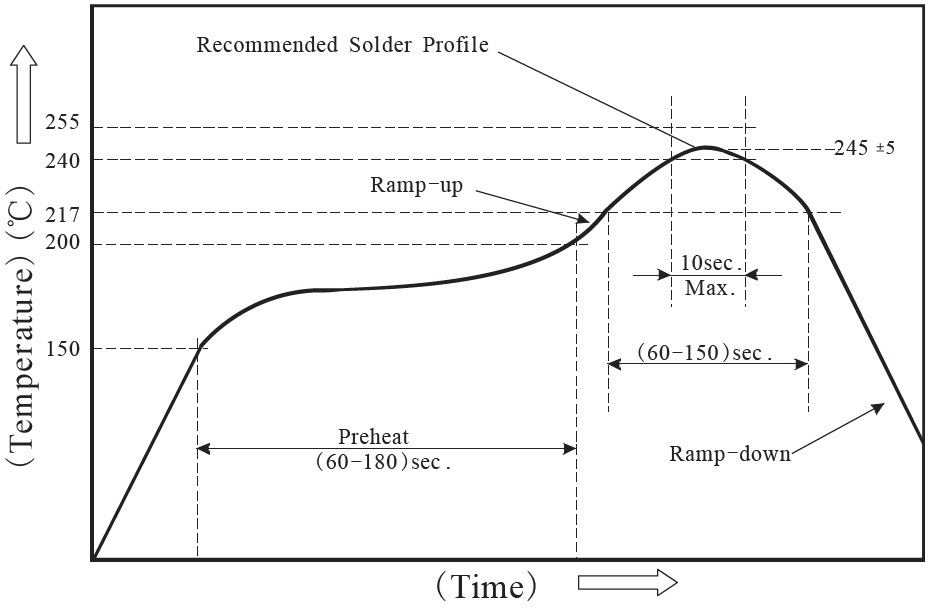

2. Reflow soldering:

Use the conditions shown in the under figure of Pb-free reflow soldering.

SMD Reflow soldering

Note:

a) Reflow soldering should not be done more than twice.

b) Stress on the LEDs is prohibited during heating in soldering process.

c) After soldering, cool down the products before next steps.

3. Clean:

It is recommended that use alcohol as solvent for cleaning after soldering. Cleaning is to go under 30 degree for 3 minutes or 50 degree for 30 seconds. When using other solvents, it should be confirmed beforehand whether the solvents will be dissolve the package and the resin or not.

Ultrasonic cleaning is also an effective way for cleaning. But the influence of ultrasonic cleaning on LED depends on factors such as ultrasonic power. Generally, the ultrasonic power should not be higher than 300W. Before cleaning, a pre-test should be done to confirm whether any damaged to LEDs will be occurring.

Note:

This general guideline may not apply to all PCB designs and configurations of all soldering equipment. The technique in practice is influenced by many factors, it should be specialized based on the PCB designs and configurations of the soldering equipment.